Up to 95% Water Savings

Operates primarily in dry mode, using water only during peak demand.

Only uses water evaporation at peak ambient conditions. otherwise, it works completely dry, reducing water consumption up to 95% consumption

Close loop circuit and no stagnant water results in pre-treated water that will be kept perfectly clean and uncontaminated.

Assures always constant heat transfer with no fouling or scaling of surfaces.

Process water only needs chemical pre-treatment and periodic monitoring. No consumption or bleed-off.

Our radiator-finned heat exchangers dissipate thermal energy from process fluids into ambient air through convection, based on a carefully calculated dry temperature gradient derived from heat transfer area and fan airflow design.

We design each system with specific process fluid temperatures and ambient dry bulb conditions in mind. Ambient air naturally contains a mix of gas and humidity. When atmospheric humidity increases, the dry bulb temperature shifts along the isenthalpic line until reaching the saturation limit. This process pre-cools incoming air before it enters the finned heat exchanger, effectively boosting the system’s heat transfer capacity and cooling efficiency.

Operates primarily in dry mode, using water only during peak demand.

Optimized fan and heat exchanger design for minimal power use.

Maintains consistent cooling even in varying climate conditions.

Reduced emissions for a healthier atmosphere.

When the ambient are generally lower, during most part of the day & during winter, system operates as a dry cooler wherein the heat of the process fluid dissipate in the ambient air by convection of the air forced by the fans. This saves 80% energy cost annually.

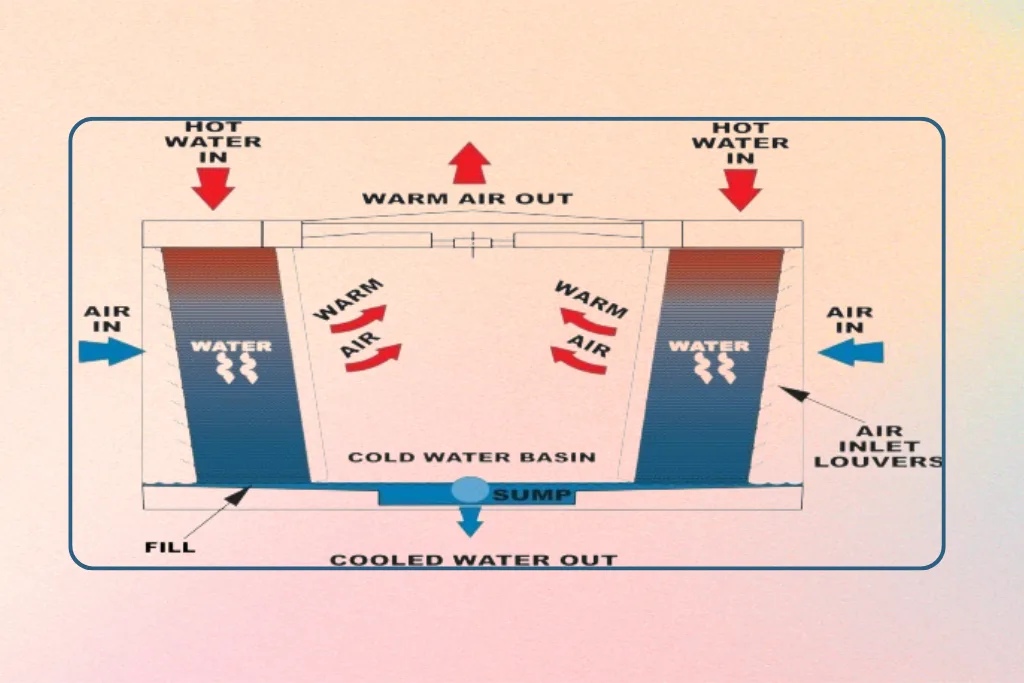

Is activated when the ambient temperatures are high. The hot ambient air humidifies while traversing these wetted cellulose pads, the water within them evaporates, increasing the cooling capacity of the tower by reducing the temperature of the air flowing through the cooling coils.

Speak to our ExpertOur adiabatic cooling towers are engineered to deliver exceptional water conservation, energy efficiency, and low maintenance—making them a smart choice for industries seeking sustainable cooling solutions.

Significant Water Savings:

Consumes only the water applied to evaporative cooling pads, reducing water usage by up to 90% compared to conventional cooling towers.

Lower Energy Consumption:

Optimized design and ambient air cooling can cut power usage by up to 40%, lowering operational costs and carbon footprint.

Reduced Evaporation Losses:

Uses ambient air to provide effective cooling, minimizing evaporation and preserving water resources.

Efficient Heat Transfer:

Lowers dry-bulb air temperature through latent heat absorption, improving cooling performance without additional energy demand.

Discover how our Adiabatic Cooling Towers can transform your cooling efficiency

Speak to our RepresentativeThe efficiency and performance is optimized with the help of advanced control systems, managed by application-specific PLCs.

VFD compatible motors/ fans regulate precisely motor speeds to match specific cooling load requirements, and minimize consumption.

Programmable operating modes gives the user the flexibility to manage their water and power consumption as needed to meet changing costs and plant operating requirements.

Adiabatic cooling is then increased until process cooling needs are satisfied or adiabatic capacity is up to 100% before power consumption is increased.

Take full command of your cooling operations with intelligent control and system management for unmatched efficiency.

Contact usExperience the future of cooling with our high-efficiency Adiabatic Cooling Towers — engineered to save water, reduce energy costs, and deliver reliable performance in any climate.